|

|

Insulation FAQs

| What does insulation actually do for my home? |

| What areas of my home should be insulated? |

| How do I know how much insulation I need for my home? |

| What is R-value? |

| Where do I find R-value information when I go to buy insulation? |

| What are the options when choosing insulation? |

| How can I be sure I'm getting the best performance from the insulation in my home? |

| Are there rebates available for installing insulation? |

| If I am adding more insulation to my home do I need to remove what I already have? |

| What Kind of Insulation Do Builders Use on Their Own Homes? |

| http://www.naima.org/Simply Insulate ReOrg/Simply Insulate/content/whatkind/builders/index.html |

| |

| What does insulation actually do for my home? |

Fiber glass insulation keeps your home cool in the summer and warm in the winter, because insulation resists the flow of heat. Heat is a form of energy and always seeks a cooler area – flowing out of the home in the winter and into the home in the summer. By reducing heat flow, a properly insulated home uses less energy for heating and cooling. In addition to being an energy saver, fiber glass insulation also acts as a sound absorber. When installed in walls and ceilings, it can reduce the transmission of sound from one room to another or from the outside. In today's noise-laden environments, more and more homeowners are soundproofing their homes. A well-insulated home increases the overall comfort of the home and adds to its resale value. Whether your home is new or old, it pays to insulate.

Go to the Top |

|

|

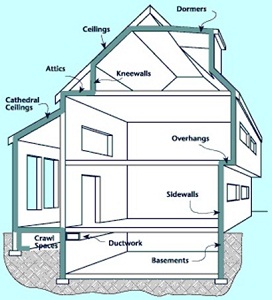

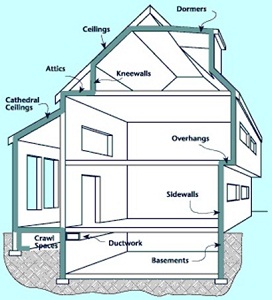

| What areas of my home should be insulated? |

|

Insulation is not just for attics and outside walls. Insulation should also be installed in other areas of your home such as ceilings with unheated spaces, basement walls, floors above vented crawl spaces, cathedral ceilings, floors over unheated garages or porches, knee walls, and in between interior walls (especially bathrooms), ceilings or floors for extra sound control.

Go to the Top |

|

| How do I know how much insulation I need for my home? |

| The amount of insulation in a home varies depending upon where you live. NAIMA has developed recommended levels of insulation for various climate zones. These recommendations are based on recommendations from the U.S. Department of Energy (DOE) and the International Energy Conservation Code which is the model building code for the United States. Click here to visit SimplyInsulate.com to learn about what zone your home is in and how much you insulation you need. Go to the Top |

|

| What is R-value? |

Insulation is identified and labeled by R-value. "R" stands for resistance to heat flow. The higher the R-value, the greater the insulating power.

Go to the Top |

|

| Where do I find R-value information when I go to buy insulation? |

Insulation is identified and labeled by R-value. "R" stands for resistance to heat flow. The higher the R-value, the greater the insulating power. Manufacturers of insulation products print R-values of their products either on the bags or on the labels. In most cases, R-values are also printed on the facings of fiber glass batts and rolls.

Go to the Top |

|

|

| What are the options when choosing insulation? |

| There are a variety of insulations to choose from including fiber glass, mineral wool, cellulose, foam and cotton. The two most common types of insulation for residential applications are fiber glass and cellulose. There are several things to consider before making an insulation decision: |

| Thermal Performance – Installed R-value |

| When insulating a home, it is important to get the R-value specified by the builder or the local building code. It's also important that the product provide long-lasting thermal performance. While R-value "per inch" is promoted by some manufacturers, the overall R-value installed is what counts. Fiber glass insulation products come in R-values ranging from R-11 to R-38 for fiber glass batts and rolls. Fiber glass and rock and slag wool insulation can be blown in an attic to nearly any R-value. More R-value alternatives provide greater flexibility in meeting code energy requirements in your area. |

| Lifetime Performance |

| In order to ensure the expected energy savings, it is important that the insulation does not deteriorate, or settle, over time. Fiber glass batts and rolls do not settle. Fiber glass and rock and slag wool loose-fill insulations may settle approximately 1-3% resulting in virtually no impact on the thermal performance of the insulation. In contrast, cellulose insulation not only settles to a much greater degree (approximately 20%), but also at a higher rate. If cellulose insulation is being considered, make sure the installer understands that most cellulose insulations settle in attic loose-fill applications – that's a significant loss of insulating effectiveness. In fact, the Insulation Contractors Association of America recommends that an additional 25% of thickness be added for cellulose insulation to compensate for this extreme loss of R-value. |

| Fire Safety |

| Fiber glass and cellulose perform very differently in terms of fire safety. Fiber glass insulation is naturally non-combustible because it is made from sand and recycled glass. Fiber glass insulation requires no additional fire-retardant chemical treatments. Most facings attached to fiber glass insulation are combustible and should never be left exposed. Other special flame-resistant facings may be left exposed where desired, such as on a basement or crawl space wall. Cellulose insulation is made primarily of ground-up or shredded newspaper, which is naturally combustible. To protect against fire, cellulose insulation is heavily treated with fire retardant chemicals. Though cellulose is treated with fire retardants, it is not fire proof. This means the insulation could still burn if exposed to a heat source. Also some tests have shown that fire retardant chemicals can lose their effectiveness over time. Tests conducted by the California Bureau of Home Furnishings and Thermal Insulation demonstrated that most cellulose samples failed the standard fire safety test only six months after installation. Smoldering and re-ignition problems present additional concerns with cellulose insulation should a fire start. Rock and slag wool insulations are used in passive fire resistance products. |

| Moisture |

| Insulation will lose its insulating efficiency or R-value when wet. Fiber glass and rock and slag wool insulation are not absorbent and, if exposed to moisture, will not wick up or hold water. They will dry out and retain their original R-value. Because cellulose is made from shredded newspaper, it will absorb and hold moisture, reducing energy savings. If soaked, cellulose will mat down and the thermal performance can be permanently reduced. Some cellulose insulations are actually applied with water added by what is called a wet-spray method. Wet-spray applications do not achieve their R-value until dry. A study conducted by the NAHB Research Center in 1997, found that cellulose insulation had installed moisture content greater than 40%. According to the study, under summer conditions, the walls dried rapidly to below 30% in the first day, but under fall and spring conditions, the walls dried much slower and were still above 30% when the dry wall was installed. Waiting until the cellulose is dry to cover up is difficult with today's building construction schedules. If wet-spray applications are covered up too soon, moisture problems can occur. Not only does the insulation efficiency suffer, but moisture can affect other building components, such as wood studs, drywall and metal building components which can suffer corrosion from moisture and salts. Moisture can also lead to a number of additional indoor air quality problems by promoting mold and mildew growth. |

| Air Infiltration |

| Thermal insulation, whether fiber glass or cellulose, when installed in side walls has very little to do with air infiltration. The U.S. Department of Energy estimates that up to 40% of a home's heat loss can be from air infiltration. But only 14% of the total loss from air infiltration occurs through side wall cavities, and most of that is around electrical outlets, a problem easily solved with inexpensive, easy-to-install electrical insulated outlet gaskets. Air infiltration generally occurs in the areas of a home that are not insulated, such as around windows, doors, fireplaces, HVAC ductwork and perimeter joints. It can, and should, be controlled with the use of housewrap, proper caulking, and sealing of band joists, sill plates, header plates, and insulation around doors, windows, electrical outlets and other openings. Recently there have been claims that some insulation products are better because they reduce air infiltration. Numerous research studies have been conducted to investigate this issue, among them studies by the National Association of Home Builders Research Center, researchers at Penn State University, and by a St. Louis utility. The research consistently demonstrated that if a wall cavity has been properly constructed, using drywall, sheathing and caulking, very little air will flow through the wall cavity regardless of the type of insulation. |

| Environmental Benefits |

As the environmental consciousness of Americans has been heightened, the building industry has responded. This kind of rethinking has led to a strong push to use building materials with lower environmental impact. Fiber glass insulation manufacturers have responded to this call for conservation by using increasing amounts of recycled materials in their products. As an industry, fiber glass insulation manufacturers recycle more material by weight (glass cullet – up to 40%) than any other type of insulation used in the building and construction sector. The environmental benefits of fiber glass insulation, however, go far beyond its recycled content when analyzed from a life-cycle perspective. A life-cycle analysis is an appraisal of the environmental impacts connected with a product through an examination of the product's environmental traits during many stages including pre-manufacturing; manufacturing; distribution/packaging; use, reuse, maintenance; and waste management. In reviewing each of these stages, a life-cycle evaluation of fiber glass clearly shows its environmentally beneficial attributes. As an example, consider fiber glass versus cellulose insulation. Cellulose manufacturers claim environmental benefits, even though they may be removing newsprint from an existing recycling loop. More trees must be cut and more energy used to make new newsprint and cardboard to make up for what has been used for cellulose insulation. And when it comes to insulating the same size home, pound for pound, it takes up to three times more cellulose than fiber glass to achieve the same insulating efficiency. Both insulations use the same amount of virgin material but the virgin material in fiber glass is sand – which is classified by the U.S. Environmental Protection Agency as a "rapidly renewable resource."

Go to the Top |

| How can I be sure I'm getting the best performance from the insulation in my home? |

Perhaps the most important consideration of all is the installation of the insulation. Regardless of the insulation type, the full R-value can only be achieved with proper installation. To help ensure the proper installation of fiber glass, rock and slag wool insulation, the North American Insulation Manufacturers Association (NAIMA) provides strong outreach support for professional contractors. It provides training programs to recruit, train and place men and women in careers as residential insulation installers. In addition, NAIMA acts as an industry resource for architects, builders, homeowners and the general public. If you intend to install fiber glass, rock wool or slag wool insulation yourself, follow product installation instructions carefully. See the following publications for information on installing fiber glass batts, rolls and loose-fill insulation:

Go to the Top |

|

|

| If I am adding more insulation to my home do I need to remove what I already have? |

Since R-values are cumulative, there is no need to remove what you already have. By layering two different batts together, you get the combined R-value of both batts. For example, two layers of R-19 batts will give you a total of R-38. Be sure to use unfaced R-19, R-25 or R-30 fiber glass batts and lay them cross-wise to the existing insulation covering the joists. Do not put a product with a vapor retarder or facing on top of existing insulation. If there is no insulation in your attic, use R-30 or R-38 full width, faced batts, or fiber glass loose-fill installed to the required R-value.

Go to the Top |

|

|